Premier Aluminum Llc Fundamentals Explained

Premier Aluminum Llc Fundamentals Explained

Blog Article

Premier Aluminum Llc Can Be Fun For Everyone

Table of ContentsThe 2-Minute Rule for Premier Aluminum LlcTop Guidelines Of Premier Aluminum LlcThe Ultimate Guide To Premier Aluminum LlcAn Unbiased View of Premier Aluminum LlcNot known Details About Premier Aluminum Llc

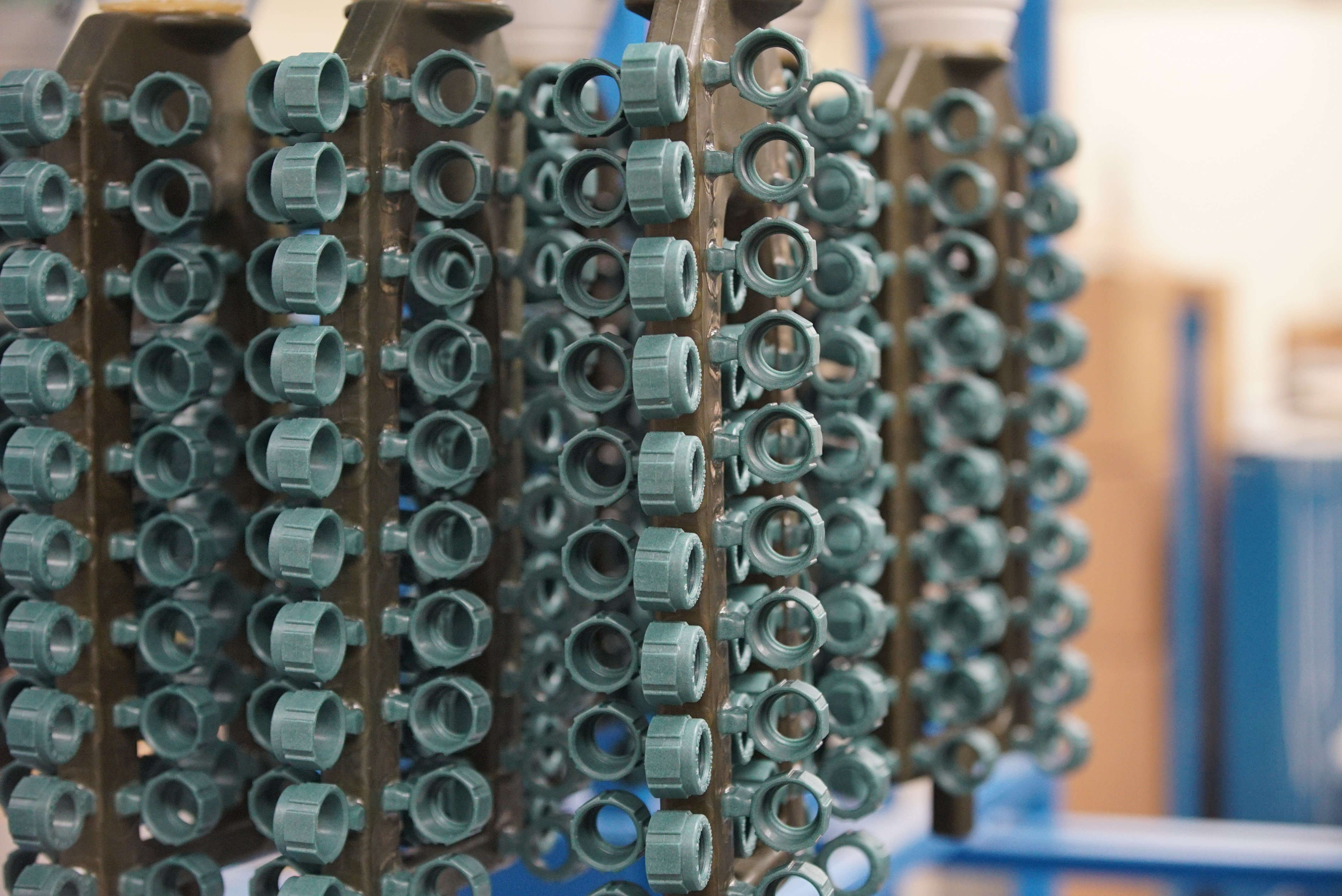

Likewise, mold and mildews for the versatile process of long-term mold and mildew spreading are typically made from steel. Aluminum is an excellent selection for irreversible mold and mildew casting, while ferrous alloys, like steel, are too hot in their molten state. As you can see, there are a variety of aspects to consider prior to determining which material, aluminum or steel, is appropriate for your item.According to a 2020 report, the demand for aluminum die spreading climbed to nearly 6%, and it's approximated the production procedure will certainly represent 55% of the automobile section. Other industrial markets, including aerospace, telecommunication, and aquatic industry, are likewise on the quest for light weight aluminum. That said, It is very important for makers to know the readily available light weight aluminum die-casting firms to fulfill their requirements.

We will likewise describe what they concentrate on and the technologies they use to remain cost-efficient and produce high-quality parts for different markets. Continue reading to find out more. Consolidated Metco, additionally called ConMet, is celebrated in the transport market. The company, established in 1964, assists people in the transport industry invent, design, and manufacture Aluminum and Iron structural components.

ConMet also features innovative innovations, including PreSet, Tru Turn, CastLite, and PreSet PLUS, which have transformed the industrial transport market by lowering gas and maintenance expenses and offering adaptable, lightweight product packaging. Dynacast International is yet an additional Light weight aluminum die-casting company that tops our checklist for a good factor. The manufacturing firm offers a large variety of commercial applications, including electronics, automotive, aerospace, golf items, telecoms, and much more.

The 9-Second Trick For Premier Aluminum Llc

From establishing sophisticated design devices for light-weight to Value-Added Assembly. Headquartered in Henderson, Kentucky, Gibbs's main activities include alloy advancement and improvement of the spreading process. Chatting of the casting process. The business is ranked as a worldwide leader in both upright and horizontal die spreading processes, which aids fulfill the needs of its lasting tier-one and OEM clients.

The business concentrates on manufacturing and designing a large range of aluminum components, from automotive seating support and comfort systems to aerospace tubes and made assemblies. The firm is also committed to supplying high-performance components that are adeptly crafted. Actually, it provides high-volume components to much of the heading Global OEMs in the mobile equipment markets.

The Best Strategy To Use For Premier Aluminum Llc

The surname in today's listing is Alumcast, a leading Mexican firm offering High Stress Pass Away Casting (HDPC) and machining options to automobile, food, general, and specialized sectors. Established in 2018, this new-age factory supplies very ended up light weight aluminum spreadings to Mexico and the U.S.A.. The company counts on leveraging contemporary tech and continual renovation, and additionally imagines coming to be a market leader serving its customers with just the very best.

With a group of knowledgeable engineers and the most current cutting edge equipment, our business provides top quality parts across numerous industrial applications. Call us today, and allow's take your production game to the next level!.

Typically, the better a style error is uncovered in the developing cycle, the better its price. When tooling needs to be junked or remodelled, the effect appears in prices and hold-ups. Nevertheless, revamping a die cast die additionally includes cost in decreased die life and potential adverse quality impacts.

The 2-Minute Rule for Premier Aluminum Llc

There are a number of prototype methods from which to select. The mechanical buildings of a plastic or machined part are fairly various from those of a die spreading.

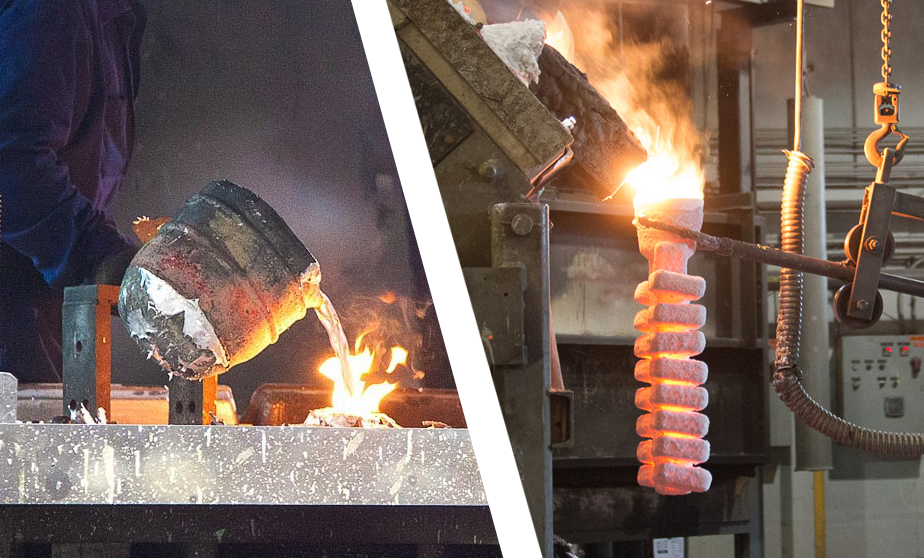

We can after that carry out numerous functional tests. Nevertheless, homes are dissimilar to die spreadings and parting line conditions, and occasionally, the draft needed in a die casting is not stood for in a machined model. Sand casting, investment spreading, and rubber plaster-mold spreadings are some gravity cast processes made use of for prototyping.

Contrasted to high-pressure die spreading, sand cast prototypes call for thicker walls and bigger tolerances, so features that could be "as-cast" in a die spreading may require to be machined in a sand casting. These processes make use of lower-cost tooling than high-pressure die spreading but have a lot higher item prices. These style, building, and price tradeoffs need next to be taken into consideration when assessing the very best prototype method.

Prototype pass away casting passes away can be created in much shorter preparation and at less expense because they utilize standard componentslike an existing die baseand pre-hardened, uncoated tool steels that do not require post-machining warm treatment. Aluminum Castings. The device will not run as efficiently as a typical manufacturing pass away, and flash will need to be gotten rid of by hand rather than with a manufacturing trim die, yet component expenses will certainly be a lot less than for machined or gravity-cast prototypes

Premier Aluminum Llc for Dummies

(https://anotepad.com/note/read/4mnaxd4k)Chicago White Metal provides every one of the model options you read about today if you want more information about prototyping or would like to speak to one of our group participants, e-mail or call (630) 595-4424.

Aluminum spreading is a kind of metalworking procedure that includes pouring liquid steel right into a mold or form. Light weight aluminum casting might be a variation of this that utilizes only aluminum and aluminum alloys due to the liquid metal that's put into the mold. Light weight aluminum castings are used to make complex and detailed die spreading components really efficiently.

Report this page